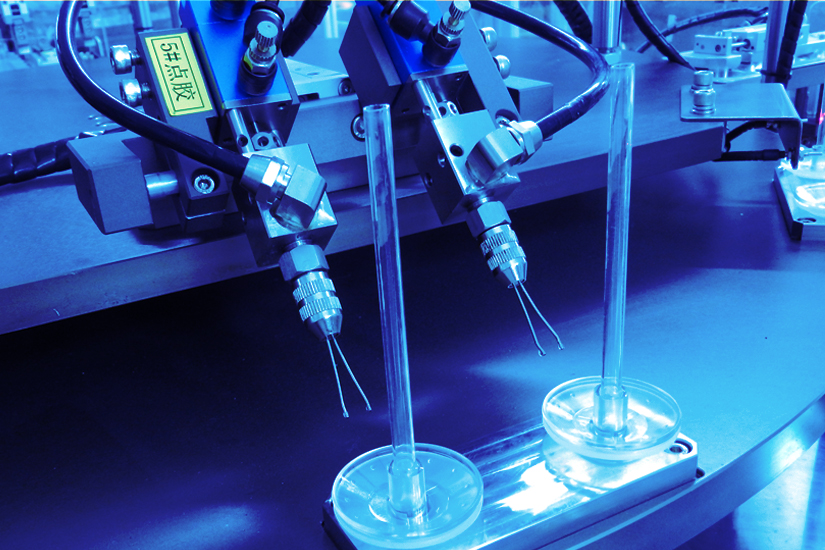

The blue air needle is a high-quality medical consumable product, usually used for injecting drugs or drawing blood. It is made of high-quality materials to ensure safety and reliability. The blue air needle is exquisitely designed, with little stimulation during injection, easy to use, and suitable for various injection scenarios. Blue air needle products usually have the following characteristics: 1. High-quality materials: Made of medical-grade materials, safe and sterile, in line with medical and health standards. 2. Precision design: The needle tip is sharp, the puncture pain is small, and the injection process is more comfortable. 3. Safe and reliable: Strict quality control to ensure stable product quality and reduce the risk of use. 4. Multiple specifications to choose from: The needle size is diverse and suitable for different purposes and different patient groups. As one of the important consumables in the medical industry, the blue air needle is widely used in medical institutions such as hospitals and clinics, providing medical staff with safe and convenient injection tools, while bringing patients a more comfortable treatment experience.

The use of automated equipment in the production process of modern medical consumables products has brought many benefits, which has a positive impact on the medical consumables industry and enterprises.

1. Improve production efficiency: Automated equipment can achieve fast and precise production, greatly improving production efficiency. Compared with manual operation, automated equipment can complete production tasks faster, shorten production cycles, and increase output.

2. Reduce production costs: Automated equipment can reduce labor costs and improve production efficiency, thereby reducing production costs. Enterprises can achieve higher production benefits and reduce the production cost of each unit product through automated equipment.

3. Improve product quality: Automated equipment can reduce the impact of human factors on product quality and ensure product consistency and stability. Precision automated production processes can reduce product defect rates and improve product quality and reliability.

4. Promote technological innovation: The application of automated equipment has promoted technological innovation in the medical consumables industry. With the help of automated equipment, enterprises continue to improve production processes and technical levels, and promote the industry to develop in the direction of intelligence and digitalization.

5. Enhance competitiveness: By improving production efficiency, reducing costs, and improving product quality, enterprises can enhance their own competitiveness, better meet market demand, expand market share, and achieve sustainable development.

In summary, the use of automated equipment has brought significant benefits to both the medical consumables industry and enterprises, promoted the development of the industry and enhanced the competitiveness of enterprises, and provided more efficient and reliable solutions for the production and supply of medical consumables products.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

方案_13.jpg)

方案_17.jpg)

方案_15.jpg)

方案_09.jpg)

中文

中文

English

English