Extension tubes in medical consumables pipelines are tubular items used to connect different medical devices and instruments. They are usually used to extend the length of infusion tubes, catheters, etc. to facilitate medical staff to operate or provide better treatment effects. Extension tubes can help medical staff operate more conveniently and flexibly during treatment or surgery, and can also reduce patient discomfort.

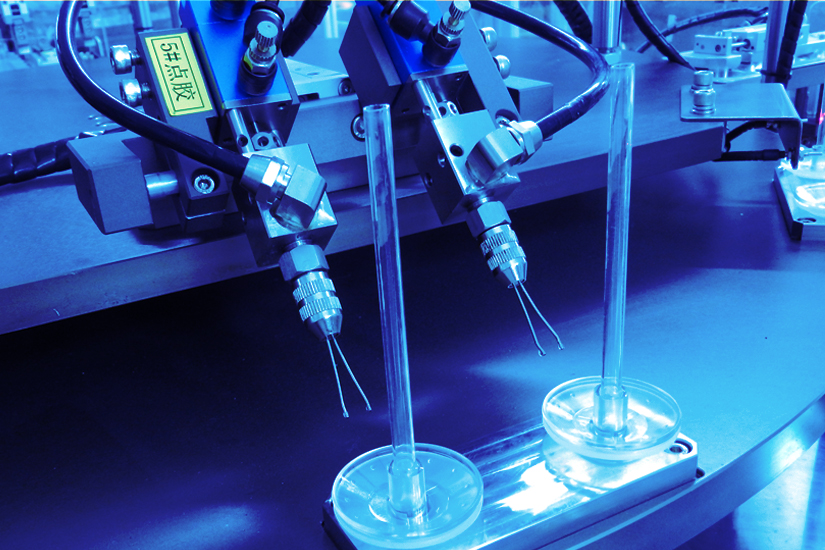

Due to the large-scale production of extension tubes, although they are disposable products of medical consumables, this product has also fallen into price competition in the market. Medical consumables manufacturers can increase production and reduce costs while ensuring quality. The emergence of automatic assembly machines for extension tubes solves this pain point. The benefits of using automatic assembly machines for extension tubes include:

1. Improve work efficiency: Automatic assembly machines can realize fast and accurate assembly of extension tubes, reduce manual operation time, and improve work efficiency.

2. Reduce human errors: Automatic assembly machines can reduce the occurrence of human errors and ensure product quality and assembly accuracy.

3. Save costs: Automatic assembly machines can reduce labor costs and improve production efficiency, thereby saving the production costs of enterprises.

4. Improve product quality: Automatic assembly machines can improve product consistency and quality stability, ensuring that products meet standard requirements.

Using extension tube automatic assembly machines can improve production efficiency, reduce costs, and reduce human errors, thereby improving product quality and corporate competitiveness.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

方案_13.jpg)

方案_17.jpg)

方案_15.jpg)

方案_09.jpg)

中文

中文

English

English