In the production process of mechanical timers, it is an essential task to detect whether the timer is running accurately. Traditionally, this detection often relies on manual operation, and the following pain points may occur:

1. Inefficient manual operation: Manual operation requires picking up the timers one by one to compare and record the time, which is time-consuming, labor-intensive and prone to errors. A large amount of repetitive labor may cause workers to be tired and inattentive to details.

2. Influence of subjective factors of workers: Due to the influence of human factors, different workers may have different standards and judgments, resulting in inconsistent and inaccurate results. This may affect the quality of the product and customer satisfaction.

3. High cost and resource consumption: Manual operation requires hiring workers and investing resources such as training, supervision and management. At the same time, additional time and cost may be required to deal with errors and corrections caused by manual operation.

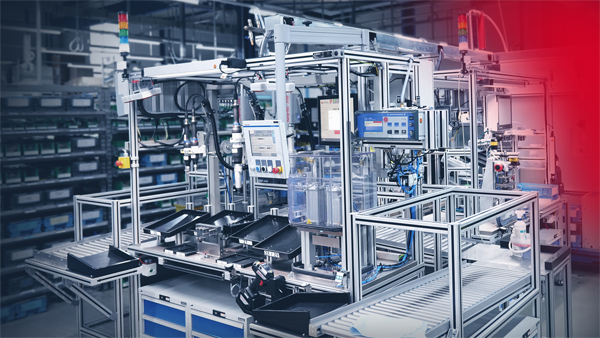

The introduction of automated equipment can effectively solve the above problems, and the specific effects are as follows:

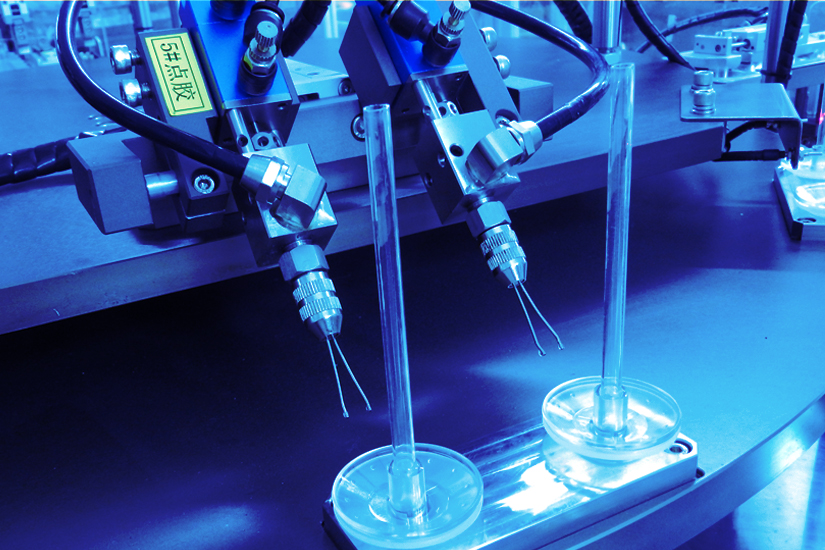

1. Improve detection efficiency: Automated equipment can achieve high-speed, continuous and accurate timer detection. It can quickly acquire and record data, complete a large number of tests in a short period of time, and quickly generate result reports.

2. Improve detection accuracy: Automation equipment can measure and compare the time of the timer more accurately through precise sensors and algorithms. It can eliminate human subjective factors, provide consistent and reliable results, and improve product quality and consistency.

3. Reduce costs and resource consumption: The use of automation equipment can reduce the demand for human resources and reduce costs in training, management and supervision. At the same time, it can reduce waste caused by human errors and improve work efficiency.

4. Functional expansion and flexibility: Automation equipment can integrate multiple functions, such as data storage and analysis, anomaly detection and tracking, etc. This provides factories with more options and flexibility to meet different needs and respond to changing market demands.

The introduction of automation equipment in the aging detection process of mechanical timers can improve efficiency and accuracy, reduce costs and resource consumption, and bring higher production benefits and product quality.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

方案_13.jpg)

方案_17.jpg)

方案_15.jpg)

方案_09.jpg)

中文

中文

English

English