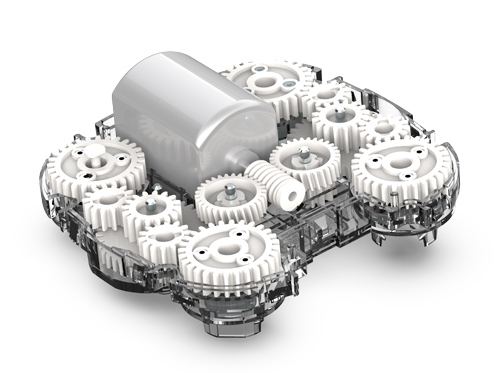

The massager movement gearbox is one of the core components of the massager, and its composition usually includes the following parts:

1. Gear: Gear is the most important component in the movement gearbox, which is used to transmit and convert power. According to different functional requirements, multiple gears can form a gear system to achieve different massage movement modes.

2. Shaft: The shaft is a part that supports and connects the gears, and bears the power of rotation and torque. It plays a positioning and supporting role in the movement gearbox.

3. Bearing: The bearing is used to reduce the friction of the gear during rotation, and to support and fix the position of the shaft. It can provide smooth rotation and long service life.

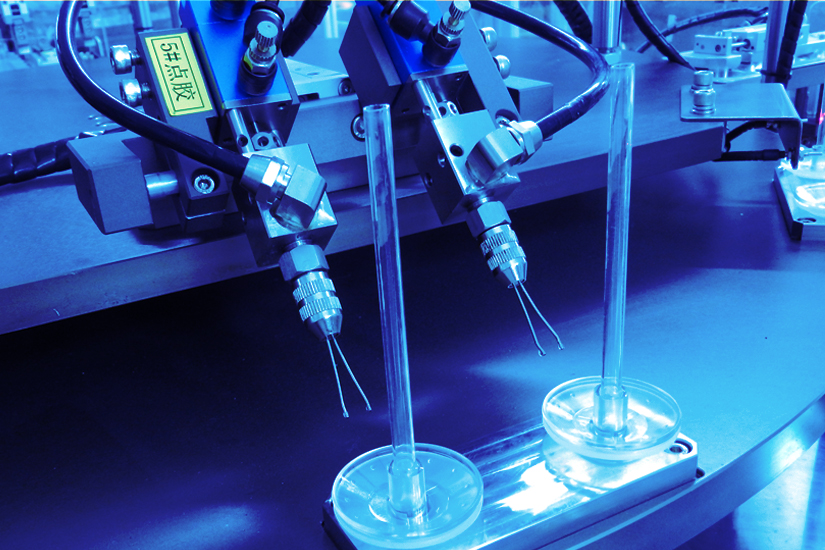

The application of automated assembly machines in the production of massage chair movement gearboxes can bring many benefits:

1. Improve production efficiency: The automated assembly machine can automatically complete the assembly process of the massage chair movement gearbox, which can greatly improve production efficiency and reduce labor costs compared to manual assembly.

2. Ensure assembly quality: The automated assembly machine has highly precise control and monitoring capabilities, which can ensure the consistent and reliable assembly quality of the massage chair movement gearbox and reduce product defects caused by human operation errors.

3. Improve production consistency: The automated assembly machine can ensure that the components and accessories of each massage chair movement gearbox can be assembled according to unified standards, improving the consistency and stability of the product.

4. Reduce costs: The automated assembly machine can reduce manual participation and labor intensity, reduce production costs, and improve corporate competitiveness.

In short, the application of automated assembly machines in the production of massage chair movement gearboxes can improve production efficiency, ensure assembly quality, and improve production consistency, thereby bringing more benefits to the massage chair industry.

Recommended news

![]() 2024 | 11 | 08Gear assembly machine - efficient, stable and in...

2024 | 11 | 08Gear assembly machine - efficient, stable and in...![]() 2024 | 11 | 07Coffee valve automatic assembly machine: intelli...

2024 | 11 | 07Coffee valve automatic assembly machine: intelli...![]() 2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

2024 | 11 | 07Medical consumables automation-extension tube au...Using an extension tube automatic assembly machine can improve production efficiency, reduce costs, and reduce human err...

方案_13.jpg)

方案_17.jpg)

方案_15.jpg)

方案_09.jpg)

中文

中文

English

English